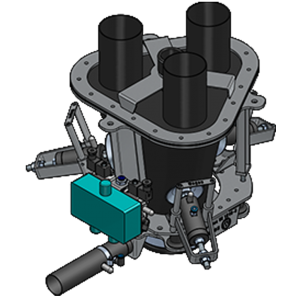

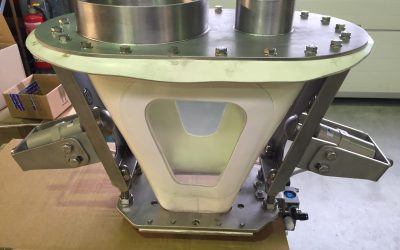

In extrusion processes, it is important to create consistent product flows, but often bulk goods being fed build up in the extruder inlet area or adhere to the walls of the hopper. The ROWEFLEX® pre-hopper offers the customer the flexible solution for merging several bulk goods. Thanks to its individual design, it can be flexibly adapted to your system and, as opposed to conventional metal hoppers, ensures continuous product entry. All discharge aids are located outside the product space and do not impair the free product flow, meaning that the product is not contaminated in any way. ROWEFLEX® pre-hoppers are available in several standard designs and can be customized to the customer’s system. We match your needs flexibly in planning and development.

Constant extrusion processes

Highlights of the ROWEFLEX® pre-hopper

The special design is extremely efficient and effective

Thanks to its individual construction, the pre-hopper is more effective and cleaner than conventional metal hoppers. The product is continuously and securely fed, and the attached discharge aids counteract product buildup. With individual planning, existing systems can be retrofitted at any time. We can match your specific, individual needs and implement them without difficulty.

- Adaptation of the inlets and outlets to on-site circumstances

- Conform to FDA requirements

- Electrically conductive for use in an ATEX zone

- Flexible transition from the dosing device to the extruder

- Special sizes to meet customer wishes

- Various rubber materials for a diverse range of application areas

The optimal solution for extrusion processes in every area

During the manufacturing process, we specifically match your needs and wishes and can also easily retrofit existing systems with our customized solutions. In this way, the ROWEFLEX© pre-hopper has already satisfied customers in the following areas of application with its highly flexible properties:

ROWEFLEX® Materials

The material is tailored to your needs according to the purpose and application area. We always have a wide selection of the most diverse elastomers in stock and can also test them in direct conjunction with your product.

We would be happy to advise you in the selection of a material.

| Material | Rubber quality | Color | FDA-conform | Electrical conductivity |

| NK | Natural rubber | beige | – | – |

| NK w | Natural rubber | white | + | – |

| PG | Natural rubber | grey | – | – |

| CR w | Neoprene | white | + | – |

| CR sw | Neoprene | black | – | + |

| EP sw | EPDM | black | + | + |

| EP w | EPDM | white | + | – |

| NBR sw | Perbunan | black | – | + |

| NBR w | Perbunan | white | + | – |

| SI | Silicone | transparent | + | – |

*Extract of the material portfolio